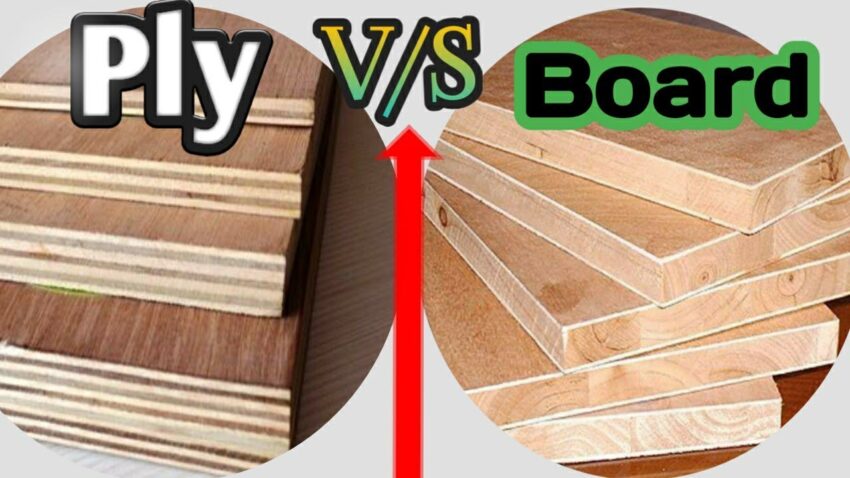

Plywood and plyboard are both engineered wood products widely used in construction, furniture making, and various other applications. They have similar purposes and characteristics but differ in their composition and manufacturing processes, which can influence their cost. Let’s explore the differences between plywood and plyboard and discuss which one is generally cheaper.

Plywood:

Plywood is a type of engineered wood made from thin layers of wood veneers, called plies or laminae. These veneers are glued together with the grain direction of each ply perpendicular to the adjacent ones, creating a strong and stable panel. The number of plies can vary, with the most common plywood types having three or more layers.

Higher-grade plywood tends to have fewer defects and a smoother surface, making it more suitable for visible applications in furniture and cabinetry.

The manufacturing process of plywood involves slicing or peeling the wood logs into thin sheets, which are then dried, layered, and bonded using adhesives, usually phenol-formaldehyde or urea-formaldehyde resin. The resulting panel is pressed under high pressure and heat to create a strong and uniform product.

Plyboard:

,Also known as particle board or chipboard, is another type of engineered wood product, but it is different from plywood in composition and manufacturing process. Plyboard is made from wood chips, sawdust, or other wood particles mixed with resin or binder. These wood particles are combined under pressure and heat to form a panel. Unlike plywood, the particles in plyboard are not arranged in layers but are randomly distributed throughout the board.

Plyboard is generally considered less strong and durable than plywood, especially in terms of load-bearing capacity and resistance to moisture. However, it is often more affordable and can be a cost-effective option for non-structural applications or hidden components in furniture and cabinets.

Cost Comparison:

When it comes to cost, plyboard tends to be cheaper than plywood. The manufacturing process of plyboard involves fewer steps and simpler technology, resulting in lower production costs. Additionally, the materials used in plyboard, such as wood particles and resin, are generally more economical than the carefully selected veneers used in plywood.

Moreover, plywood’s superior strength, durability, and appearance contribute to higher prices compared to plyboard. Plywood’s versatility and ability to withstand different environments and stress factors make it a preferred choice for structural applications. Which further justifies its relatively higher cost.

Nevertheless, it’s crucial to take into account the distinct application and demands of your project while making a choice between plywood and plyboard. If you need a load-bearing and durable material for structural purposes or visible surfaces. Plywood may be a more suitable choice, even if it comes at a slightly higher cost. Alternatively, if your project deals with non-structural elements or if you’re working within a budget, plyboard presents a cost-effective alternative.

In conclusion

Both plywood and plyboard have their respective advantages and disadvantages. Plywood is generally stronger, more durable, and aesthetically appealing but comes at a higher cost. Plyboard, being more affordable, can be a practical choice for certain applications where strength and appearance are not critical factors. Assess your project requirements and budget constraints to determine the most suitable option for your needs. Therefore, it’s crucial to compare prices based on the particular type and grade of plywood or plyboard you are contemplating.